TAIL GAS TREATMENT

Conventional Claus Suphur Recovery Units are limited because of equilibrium limitation and a three stages or four stages sulphur recovery unit cannot meet the minimum environmental pollution agency levels. This involves a tail gas treating unit at downstream of sulphur recovery unit.

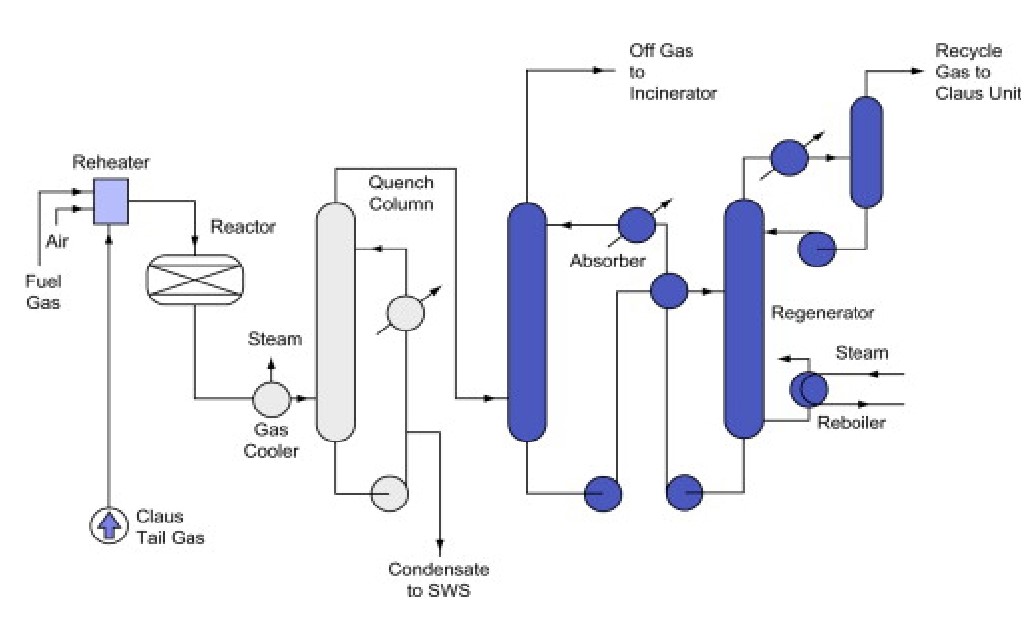

The tail gas treating process consists of a catalytic reduction section, a feed conditioning section and a solvent section. In the catalytic reduction section, reducing gas (H2) is mixed with the tail gas of sulfur recovery unit and passed through a catalytic bed so that all the sulphur compound are reduced to H2S. In the feed conditioning section, the hot gas leaving the catalyst bed is cooled first in waste heat boiler followed by direct contact with quench water. The cooled gas can then be contacted with a selective gas treating solvent in the solvent section so that nearly all the H2S is absorbed. The treated gas flows to the incinerator for oxidation of the remaining sulphur compounds. The rich solvent is regenerated to strip out the H2S, which is recycled back to front end of sulphur recovery unit. With the tail gas treating unit to capture nearly all of the unrecovered sulphur leaving the sulphur recovery unit, near complete sulphur recovery is possible even though sulphur recovery unit only recovers 94-97% of the sulfur in the feed gas. The process can achieve overall sulphur recovery in excess of 99.9% resulting in SO2 concentration in the incinerator effluent of 250 ppmv or even lower.